Table of Contents

Introduction: Efficiency, Not Budget, Defines Real Savings

In drilling projects, cost per meter is more than just a number — it’s the real measure of how efficiently time, fuel, and equipment are used. Many teams try to reduce costs by buying cheaper tools, but experienced contractors know the truth: efficiency beats discount every time.

When a project uses high-performance DTH bits for fast penetration and strong anchor plates for reliable ground support, the results are immediate — fewer delays, lower fuel use, and a smoother path to profitability.

Let’s break down why these two components are the backbone of true cost control in modern drilling.

Why “Cost per Meter” Tells the Whole Story

A low-priced tool might look good on paper, but the real cost shows up in drilling speed, energy loss, and downtime.

When bits wear out too quickly or don’t deliver consistent impact, crews spend hours changing tools instead of drilling. When anchor plates fail to hold, rework and schedule overruns follow.

Think of “cost per meter” like a health check for your project. If it’s rising, something in your process is inefficient — maybe poor energy transfer, weak materials, or excessive machine idling. Each small inefficiency can quietly inflate project costs by 10–20 percent.

That’s why cost control isn’t about cutting expenses; it’s about maintaining performance. Selecting the right tools that last longer, drill faster, and stay stable under load is how successful contractors keep their numbers — and their reputation — strong.

In fact, some managers now track cost-per-meter performance the same way they track fuel efficiency — as a live metric that shows whether crews, tools, and terrain are working in sync. By watching that number closely, they can spot small issues before they turn into costly downtime — proving that smarter monitoring is just as valuable as stronger tools.

DTH Bits: Turning Energy into Progress

Every meter drilled tells a story — and at the center of it is the bit. If the jobsite is a battlefield, this is your frontline soldier. Its geometry, strength, and material decide how efficiently impact energy turns into actual progress.

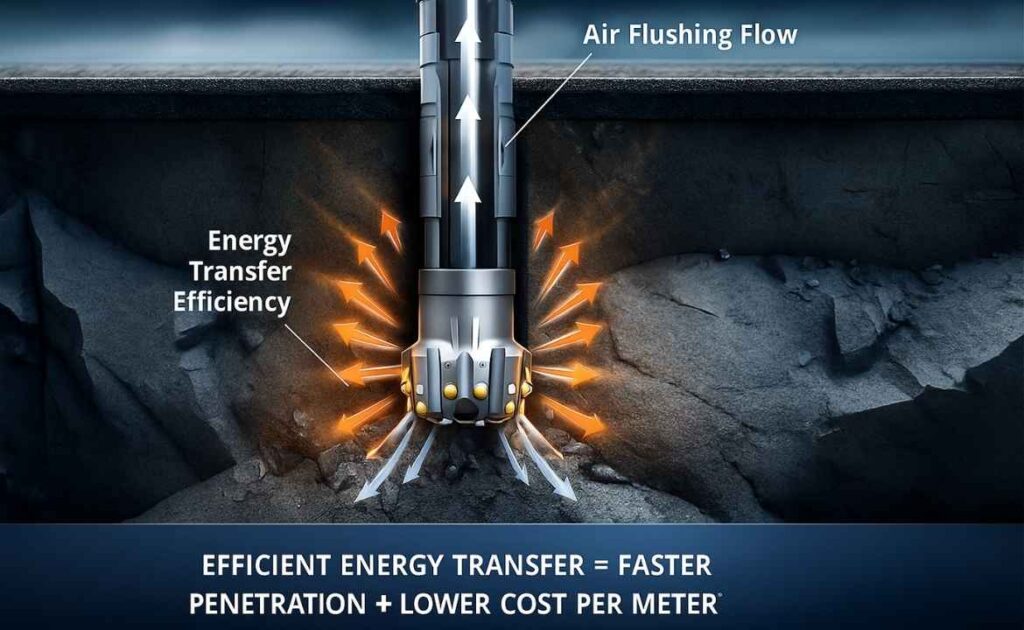

High-performance dth bits do one thing exceptionally well — they channel impact energy straight into the rock, instead of wasting it through vibration or heat. Built from premium alloy steel with tungsten-carbide inserts, they stay sharp through deep holes and keep air flushing smooth. That consistency means fewer dry strikes, steadier drilling speed, and fewer tool changes.

Anyone who’s ever replaced a bit halfway through a shift knows how costly downtime can be. A tough, efficient bit avoids all that. In practice, a 15% boost in penetration rate can save several days of work and thousands in fuel and labor — a clear reminder that the right DTH bit doesn’t just cut rock; it cuts waste.

Self-Drilling Anchor Plates: Stability That Saves More Than You Think

Drilling is only half the story. Once the hole is complete, the ground must remain stable — and this is where hidden costs often appear. In soft or fractured formations, even small collapses can trigger major rework. Each repair means new grout, extra labor, and more risk.

That’s why experienced contractors rely on self-drilling anchor plates to secure stability from day one. These plates distribute the load evenly, preventing stress concentration and collapse. Their integrated design lets teams drill, anchor, and grout in a single step — no extra machinery, no wasted time.

Different plate shapes — domed, flat, or solid — adapt to various ground conditions, ensuring every anchor holds tight. And when the system works right the first time, teams avoid the most expensive mistake of all: doing the same work twice.

System Integration: When Tools Work Together

Contractors often treat drilling and anchoring as separate tasks, but in reality, they’re parts of the same cost equation.

A good DTH bit defines the hole’s accuracy and shape; a matching anchor plate ensures the structure’s long-term integrity. When either side underperforms, efficiency collapses — literally.

When both are optimized as a system, efficiency multiplies:

- Drilling and anchoring can be completed in one smooth workflow.

- Less downtime and equipment switching.

- Consistent energy transfer and hole geometry.

- Lower fuel use and machine wear.

In one slope stabilization project, aligning bit and anchor specifications cut average drilling time by 18% and reduced rework by nearly half. That kind of improvement doesn’t come from luck — it comes from understanding how the system works as one.

Smart Choices Outlast Cheap Ones

Everyone wants to save money, but the lowest bid rarely delivers the lowest cost per meter. A weak bit slows progress. A poor anchor system invites rework. When time, fuel, and manpower start adding up, any upfront savings disappear.

The best contractors know what to prioritize:

- Choose durability over discounts.

- Choose system compatibility over convenience.

- Choose predictable performance over short-term savings.

Because in the field, efficiency isn’t measured in invoices — it’s measured in meters drilled, holes stabilized, and deadlines met. Savings aren’t about spending less; they’re about understanding more.