Key Takeaways

- Sheave units play a vital role in guiding drilling lines, reducing operational wear, and maintaining optimal line tension.

- Newer unitized sheave assemblies minimize maintenance intervals and bolster safety throughout critical lifting operations.

- Integrating real-time monitoring technologies with sheave components enables predictive maintenance, driving further efficiency gains.

In modern drilling environments, striking the right balance between safety and operational efficiency remains an ongoing challenge. Operators increasingly turn to specialized equipment to ensure reliable performance, even under the demanding pressures of oilfield activity. A critical example of this is the sheave unit, a cornerstone of the safe and efficient movement of drilling lines. Proper use of reliable sheave units, such as the fastline deflector sheave for correcting drawworks fleet angle, fundamentally enhances both the precision and dependability of rig operations.

As the industry evolves, innovations in sheave technology have led to substantial gains not only in operational reliability but also in site safety. Advanced monitoring and design features enable proactive maintenance while minimizing downtime, delivering long-term cost benefits for operators. Understanding how these improvements interplay with daily activities is key to unlocking value across drilling operations and safety management.

Table of Contents

Understanding Sheave Units in Drilling

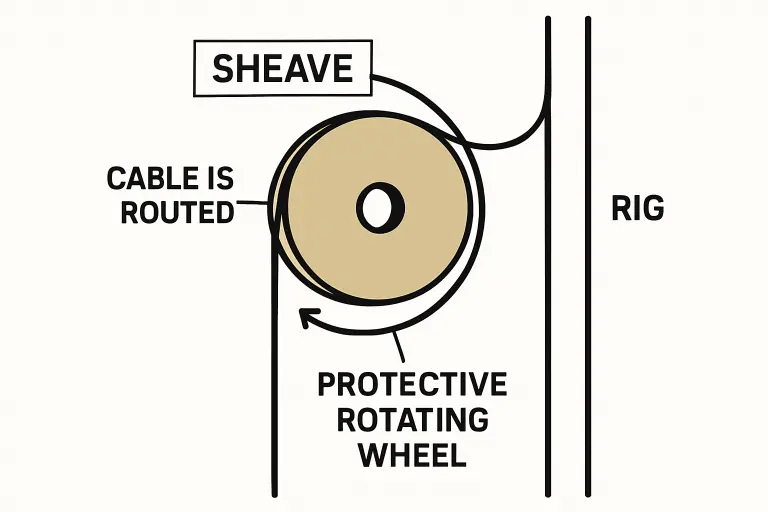

Sheave units, often called pulleys, are essential links within drilling rigs, engineered to manage the precise routing and movement of cables and drilling lines. Their primary job is to guide these lines through predefined paths, minimizing physical wear and ensuring rigorous control over cable alignment. This seemingly simple mechanical task helps prevent premature line failure, which can lead to unplanned downtime or, in more severe cases, critical safety events.

Well-maintained sheave units make a marked difference in drilling efficiency. Incorrectly aligned or poorly maintained sheave systems can compromise tension management, reduce the lifespan of expensive drilling lines, and introduce hazards that threaten both personnel and equipment. Reliable sheave performance is a baseline expectation in contemporary drilling operations, especially as highlighted in modern oilfield technologies that continue to redefine drilling efficiency and safety.

Innovations in Sheave Design

Recent progress in sheave engineering emphasizes durability and maintenance ease. Unitized sheave assemblies—comprising bearing, sheave, and seals in one pre-lubricated module—cut upkeep and simplify replacements. These designs lock out contaminants, ensure smooth rotation, extend service intervals, and reduce failure risk. For example, new solutions set benchmarks for quick, safe field servicing, lowering downtime and human exposure to hazards, aiding sector safety.

Integrating Advanced Monitoring Systems

The marriage of mechanical reliability with digital oversight marks another major leap for sheave technology in drilling. Advanced monitoring systems, designed to track real-time load, speed, and operational health, allow drill operators to predict and address wear long before lines fail or complications arise. One prominent example is the adoption of modular energy chains on drillships, exemplified by Seadrill’s use of igus technology. These innovations provide a more robust alternative to traditional service loops and have already contributed to reductions in both downtime and operational costs.

Automated analytics from these systems help operators optimize maintenance schedules and avoid unnecessary interruptions, further elevating the baseline reliability of drilling systems.

Benefits of Advanced Sheave Units

- Reduced Maintenance: Modular, pre-lubricated designs lower routine maintenance demands, eliminating frequent dismantling or re-lubrication and thereby reducing the costs associated with extended downtime.

- Enhanced Safety: Modern sheave assemblies mitigate risks linked to manual intervention, while improved seals and housings prevent the ingress of contaminants that can trigger sudden equipment failures.

- Increased Efficiency: Smooth, predictable line routing, enabled by advanced sheave designs, ensures drilling proceeds at optimal speeds while supporting eco-friendly oilfield practices that reduce waste, energy loss, and operational inefficiencies.

Implementing Sheave Units in Drilling Operations

To harness the full spectrum of benefits presented by advanced sheave technologies, operators should proceed through several key phases:

- Assessment: Audit current sheave installations to identify legacy performance gaps and high-impact modernization opportunities.

- Selection: Choose robust and compatible unitized sheave assemblies based on a detailed analysis of specific rig requirements, load conditions, and operating environments.

- Integration: Pair upgraded sheave units with digital monitoring tools to enhance oversight and ensure ongoing access to actionable performance data.

- Training: Deliver thorough operational and maintenance training to ensure seamless adoption of new systems and techniques.

Real-World Applications

The adoption of these innovations has already provided measurable benefits to several industry leaders. Seadrill’s decision to install igus modular energy chains led to significant decreases in both unscheduled downtime and service costs. These practical improvements illustrate the tangible value of integrating reliable hardware with advanced monitoring, while case examples from other operators further demonstrate the scalability of these benefits across different drilling regimes.

Significant best practices can be found by exploring industry coverage, which details how next-generation sheave designs are enabling safer, more efficient rig operations across global projects.

Conclusion

Sheave units are foundational elements in the drive to maximize both performance and safety in drilling activities. As equipment becomes more advanced, the importance of unitized assemblies and real-time monitoring only grows. Drilling companies that stay proactive in updating their sheave systems and invest in continuous training for their personnel stand to achieve best-in-class outcomes. Keeping pace with technological advancements in sheave design and integration will be key to excelling in a competitive, ever-evolving sector.